WHAT IS A CRUSHING PROCESS?

In order to make use of the rocks or ores obtained through quarrying/explosion in the Mining and Construction sectors, the materials need to be crushed to reduce them to a smaller size. We call this process SIZE REDUCTION or CRUSHING.

The goals of the size reduction are as follows:

1.) Obtaining the size or surface area required for the use of the ore or material

2.) Allowing ease of transportation and storage

3.) Separating the different minerals contained within the ore and to release them from one another

4.) Obtaining the size or surface area required for the enrichment stage.

In general, crushing is carried out in three stages, depending on the desired size of the material.

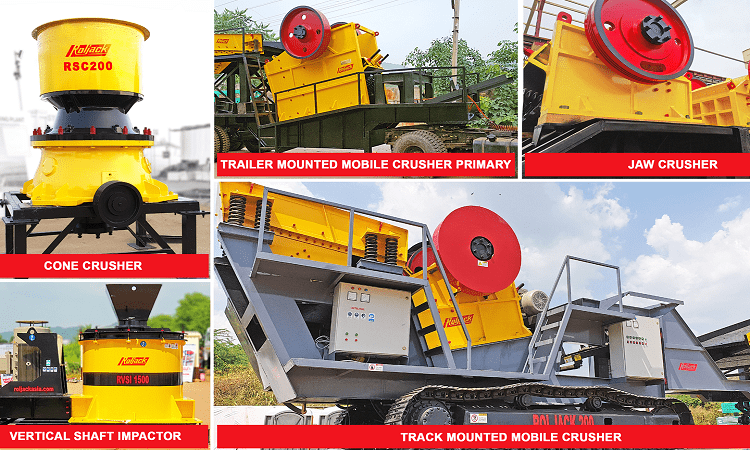

Primary Crushing

This is the first stage of the crushing process. In general, the size of the feed material, which is between 800 and 1500 mm, is reduced to between 150 and 300 mm.

Secondary Crushing

This is the second stage of crushing. Feed size, which is around 150 to 300 mm, of the rock or ore from the primary crushing process is reduced to between 50 and 80 mm.

Tertiary Crushing

This is the third stage of crushing. The size, which is around 50–80 mm, of the ore or rock from the secondary crushing process is reduced to between 5 and 12 mm.

We call the machine that performs the CRUSHING process a CRUSHING MACHINE or CRUSHER.

WHAT IS A JAW CRUSHER ?

ROLJACK Single and Double Toggle Jaw Crusher are designed and developed by advance technologies for heavy duty and continuous crushing applications with/without rubbing with high impact pressure, combined with careful selection of material and workmanship of finest quality.

WHAT ARE THE DIFFERENT TYPES OF JAW CRUSHER?

There are two main groups of jaw crushers, categorized according to their jaw movement mechanism.

- Single-toggle jaw crusher (STG)

- Double-toggle jaw crusher (DTO)

ROLJACK Single Toggle Jaw Crusher are designed for getting maximum capacity by providing continues and regular feeding and to hard crush material at higher speed with minimum power and very minimum maintenance. These crusher have been developed in the design objectives of the new generation of single toggle crusher to create the best possible geometry in crushing with rubbing & Crushing. Roljack jaw crusher feature high eccentricity and very special crushing angle to minimize maintenance & maximize production.

DOUBLE TOGGLE JAW CRUSHER (DTO)ROLJACK double toggle jaw crusher are designed to crush super hard rocks, And these crusher are designed in such way that crusher get very less maintenance in long duration crushing. When crushing takes place all the crushing load is divided in many body parts and accessories, So maintenance Or down time is very low for this type of crusher, For the ease of operation we have made this crusher oil lubricated as only oil pump is required for lubrication so no regular grease pumping or manual lubrication fir this crusher.

KEY FEATURES & BENEFITSThe reliability of RJC Series jaw crushers is based on a revolutionary extra stroke & Heavy Design Jaw Crusher, non-welded pedestal frame construction. This design provides excellent fatigue strength even in toughest quarrying or mining application. Roljack Jaw Crusher are the most productive and cost-effective jaw crusher for any primary & secondary crushing application. Jaw crusher were originally developed to crush the hardest ores and rocks so they perform extremely well also in less demanding applications, such as soft rock, recycling and slag.