VERTICAL SHAFT IMPACTOR (VSI)

ROLJACK VSI crusher use a different approach involving a high speed rotor with wear resistance tips and a crushing chamber designed to ‘Throw’ the rock against the rock. The VSI Crusher utilize velocity rather then surface force as the predominant force to break rock. In its natural state, rock has a jagged and uneven surface. As rock is ‘thrown’ by a VSI rotor against a solid anvil, it fractures and breaks along these fissures. VSI crusher generally utilize a high speed spinning rotor at the center of the crushing chamber and an outer impact surface of either abrasive resistance metal anvils or crushed rock. Utilizing crushing rock on the outer wall of the crusher for new rock to be crushed against is traditionally referred to as “rock on rock VSI”.

key features

- Very Cubicle Product

- Best For Sand Product

- 70% Compared Low

- Benificiation of Material

- Gradation consistency

- High product yield

- Simple maintenance

- High throughput capacity

- Low capacity investment

- High product yield

benefits

- Available in ROR,ROS,SOS

- Large spherical roller bearing

- Patented Hydra Lid Lifter

- Externally Adjustable Feed tube system

- Lid & Main frame lines are 60% cast chrome protected

- Tungsten carbide components in rotor

- USA renowned technology

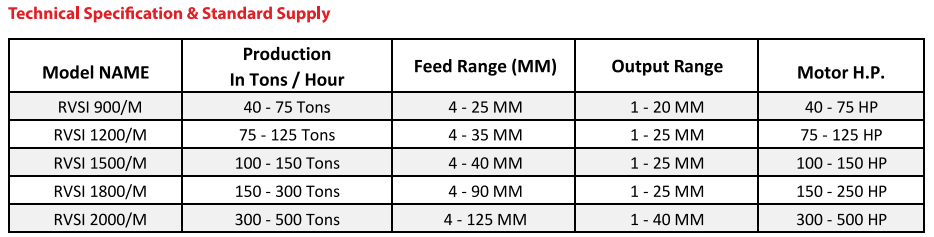

- Production capacity upto 800 T/H

- Only machine, feed Size upto 90mm

- Rotor available in 4 port, 3 port as per application